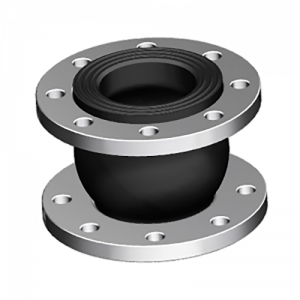

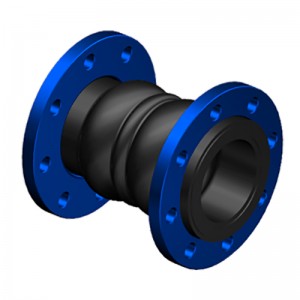

Hot Selling for China Double Bellows Dual Ball Threaded Rubber Expansion Joint

We aim to understand high quality disfigurement through the output and supply the most beneficial support to domestic and overseas buyers wholeheartedly for Hot Selling for China Double Bellows Dual Ball Threaded Rubber Expansion Joint, We often concertrating on creating new creative solution to meet request from our customers everywhere in the planet. Sign up for us and let’s make driving safer and funnier with each other!

We aim to understand high quality disfigurement through the output and supply the most beneficial support to domestic and overseas buyers wholeheartedly for China Double Ball Flexible Rubber Expansion Joint, EPDM Flexible Expansion Galvanized Pipe Coupling, We are going to not only continuously introduce technical guidance of experts from both home and abroad, but also develop the new and advanced merchandise constantly to satisfactorily meet the needs of our clients all over the world.

Details

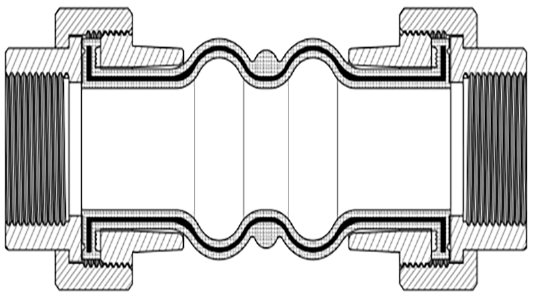

Threaded unions is used When an economical threaded pipe connection is needed, the surface of the union is available both hot-dip galvanizing and electroplating. Both ends provided with a malleable iron union with female thread BS or ANSI.

| Specifications | II | ||

| Working Pressure Mpa (Kgf/Cm2) | 1.6 (16) | ||

| Test Pressure | 2.4Mpa | ||

| Burst Pressure Mpa (Kgf/Cm2) | 4.8 (48) | ||

| Vacuum Kpa (Kgf/Cm2) | 86(660) | ||

| Materials | EPDM/NBR/SBR/NR | ||

| Diameter Range | DN15-DN80 | ||

| Connection Method | THREAD | ||

| Flanges Dimensions | BS, ANSI | ||

| Applicable Medium | Air, compressed air, water, seawater, hot water, oil, acid, alkali etc. | ||

| Loading Port: | Qingdao, China | ||

| Shipment Terms: | FOB, CFR, CIF | ||

| Production Capacity: | 50000 set | ||

| Payment Terms: | L/C, T/T, D/P | ||

| Connection: | THREAD | ||

| Flange Material: | MALLEABLE IRON, DUCTILE IRON | ||

| Period of Delivery | about 21 working days | ||

|

Threaded Union (TU) |

||||||||||||||

|

SIZE |

OAL Length |

Allowable Movement-1 |

Dimensions |

Operating Conditions |

||||||||||

|

Nominal Diameter |

Neutral OAL |

Min Installed |

Max Installed |

Max Compressed |

Max Extended |

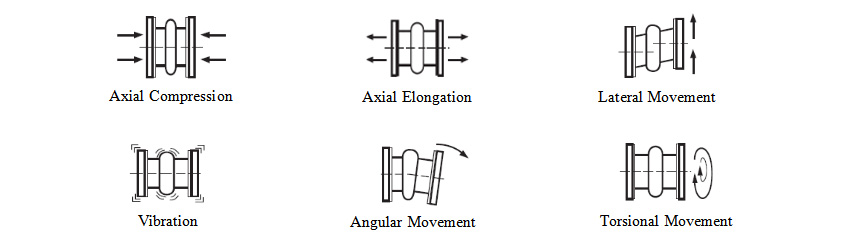

Axial Compression |

Axial Extension |

Lateral Deflection |

Angular Deflection |

OAL Fitting |

OAL Body |

Max w.p. (bar) |

Max Vacuum (in. of Hg)-4 |

|

|

Inch |

mm |

|||||||||||||

|

1/2″ |

15 |

8″ |

7.35″ |

8.12″ |

7.13″ |

8.23″ |

0.87″ |

0.23″ |

+/-0.87″ |

±32.2° |

0.92″ |

6.16″ |

150 |

26″ |

|

3/4″ |

20 |

8“ |

7.35″ |

8.12″ |

7.13″ |

8.23″ |

0.87″ |

0.23″ |

+/-0.87″ |

±32.2° |

1.00″ |

6.00″ |

150 |

26″ |

|

1″ |

25 |

8” |

7.35″ |

8.12″ |

7.13″ |

8.23″ |

0.87″ |

0.23″ |

+/-0.87″ |

±25.3° |

1.25″ |

5.50″ |

150 |

26″ |

|

1-1/4″ |

32 |

8“ |

7.35″ |

8.12″ |

7.13″ |

8.23″ |

0.87″ |

0.23″ |

+/-0.87″ |

±20.7° |

1.25″ |

5.50″ |

150 |

26″ |

|

1-1/2″ |

40 |

8″ |

7.35″ |

8.12″ |

7.13″ |

8.23″ |

0.87″ |

0.23″ |

+/-0.87″ |

±17.5° |

1.35″ |

5.30″ |

150 |

26″ |

|

2″ |

50 |

8″ |

7.35″ |

8.12″ |

7.13″ |

8.23″ |

0.87″ |

0.23″ |

+/-0.87″ |

±13.3° |

1.60″ |

4.80″ |

150 |

26″ |

|

2-1/2″ |

65 |

9.6″ |

8.95″ |

9.72″ |

7.13″ |

8.23″ |

0.87″ |

0.23″ |

+/-0.87″ |

±10.7° |

2.00″ |

5.60″ |

150 |

26″ |

|

3″ |

80 |

9.6″ |

8.95″ |

9.72′ |

7.13″ |

8.23″ |

0.87″ |

0.23″ |

+/-0.87″ |

±8.9° |

2.00″ |

5.60″ |

150 |

26″ |

|

Threaded Union (TU)-Jis Standard |

||||||||||||

|

Nominal Dia |

Nominal |

Allowable Movements (mm) |

Installation Tolerances (MM) |

OAL Fitting (MM) |

OAL Body (MM) |

|||||||

|

Inch |

mm |

Length (MM) |

Lateral Deflection |

Axial Extension |

Axial Compression |

Angular Deflection |

Lateral Deflection |

Axial Extension |

Axial Compression |

Angular Deflection |

||

|

1/2 |

15 |

180 |

15 |

10 |

15 |

15° |

6 |

3 |

6 |

7.5° |

30 |

120 |

|

3/4 |

20 |

180 |

15 |

10 |

15 |

15° |

6 |

3 |

6 |

7.5° |

30 |

120 |

|

1 |

25 |

180 |

15 |

10 |

15 |

15° |

6 |

3 |

6 |

7.5° |

30 |

120 |

|

1 1/4 |

32 |

245 |

20 |

10 |

20 |

20° |

8 |

3 |

6 |

7.5° |

35 |

175 |

|

1 1/2 |

40 |

245 |

20 |

10 |

20 |

20° |

8 |

3 |

6 |

7.5° |

35 |

175 |

|

2 |

50 |

255 |

20 |

10 |

20 |

20° |

8 |

3 |

6 |

7.5° |

40 |

175 |

Products categories

-

Phone

-

E-mail

-

Whatsapp

whatsapp

-

WeChat

Jessy Lin

-

WeChat

Ellen Zhang